Russia's Powerful Titanium Submarines: A Real Game-Changer?

Russia's titanium submarine, the Project 705 Lira, became the fastest, deepest-diving submarine in service. So fast, that it was reported they could evade Western torpedoes

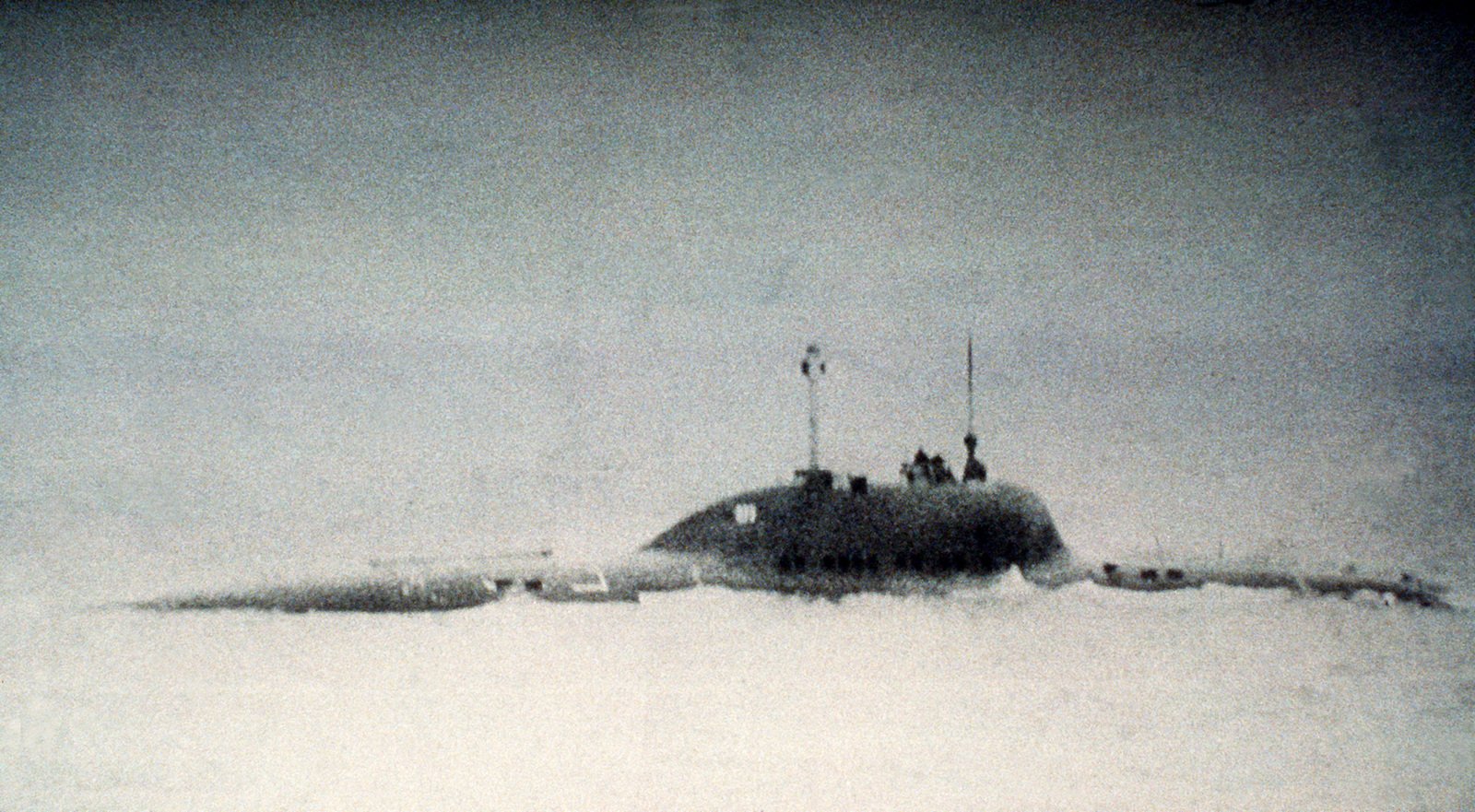

The Russian Navy's Titanium Submarines - During the Cold War, the Soviet Union produced seven Project 705 Lira (NATO-reporting name "Alfa") nuclear-powered attack submarines. These were noted for employing a powerful lead-bismuth-cooled reactor as a power source, which greatly reduced the size of the reactor compared to conventional designs, thus reducing the overall size of the submarine, and allowing for very high speeds. However, it also meant that the reactor had a short lifetime and had to be kept warm when it was not being used.

To reduce weight, the submarines' hulls were made of titanium.

Why Titanium Mattered

As Brent Eastwood previously reported, "Titanium alloy is usually stronger than steel but weighs half as less. It is more expensive, up to three to five times more than steel. Titanium is also less corrosive in salt water. It can handle more pressure during deeper dives – all the way down to 2,200 feet."

The Soviet's early nuclear-powered submarines were known to be far from stealthy, and to address the strategic disadvantage, the Kremlin sought to innovate. It sought to develop a submarine that could move faster and dive deeper than Western submarines.

The Project 705 Lira became the fastest, deepest-diving submarine in service. So fast, in fact, that it was reported they could evade Western torpedoes. The Soviet boats could also cruise at 41 knots when submerged and dive as deep as 1,148 feet. While its speed allowed it to outrun NATO torpedoes, its depth kept it out of range of other anti-submarine weapons.

Only Seven Russian Titanium Submarines Produced

Despite the capabilities of the Project 705 Lira submarines, the Soviet Union only ended up producing seven of the advanced boats. It wasn't a matter of cost – although that could have contributed to the fact – but rather titanium is very difficult to work with.

What was also notable about the boats was that analysts were caught by surprise that the Soviets could even build seven with titanium hulls.

As previously reported, in 1969, a photo analyst at the CIA stumbled upon the first indication of what would eventually become known as the Alfa-class submarine. Photographic evidence and human intelligence reports told of a submarine hull section awaiting assembly that was an oddly reflective, silvery color.

Analysts disagreed on the material. Some said it was part of a massive disinformation campaign, that the hull pieces were simply covered in aluminum paint to confuse the United States.

To successfully weld huge titanium panels on a large scale, Soviet engineers had to first create enormous warehouses that were hermetically sealed and then filled with argon, an inert gas that would not interfere with the welding process. Welders had to wear a large cosmonaut-like suit that would supply them with oxygen while inside these warehouses.

As Eastwood further added, "Titanium is rare and costly compared to iron. Titanium is not easy to shape either. Welders would need an outside oxygen source during the workday. Any misstep by the welders would create a sub that would be dangerous to take on deep dives. The higher pressure could compromise the weakened hull."

Some of the Project 705 Lira submarines did experience cracking in the hull, and repairs proved difficult, as the aforementioned coolant in the reactors had to stay heated at all times to remain liquified.

The Soviet boats were also especially noisy, which made the vessels all too easy to detect. Many of the Soviet Union's ports were not adequately equipped to service these unique submarines, so they often left their reactors running, significantly shortening the time between necessary servicing.

By the end of the Cold War, most of the Lira submarines were decommissioned and scrapped in the early 1990s. They were too expensive to maintain for cash-strapped Russia.

The Legacy of the Soviet's Titanium Subs

We really can't dismiss the importance of titanium. During the Cold War, titanium was considered a strategic material by the U.S. government, while the Defense National Stockpile Center maintained a large stockpile of titanium sponge until it was finally depleted in the 2000s.

Yet as late as 1945, there was no commercial production of titanium, and the metal only existed in tiny amounts in labs. Yet, in the years since it has formed the literal backbone of the most advanced aerospace technology on the planet.

While titanium has become a "fashionable" metal that is used in everything from skis to bicycle frames, there are now concerns that the United States simply doesn't have enough access to the material – despite it being among the most plentiful metals on the planet.

The U.S. withdrew from titanium sponge production by 2020 and now relies entirely on foreign sources, Stars and Stripes reported earlier this year.

It further noted at the same time the U.S. was retreating from the market, China's titanium sponge production capacity grew by 1,050%, according to the Department of Commerce – while Russia, which had long dominated the sector, increased its output by 66%. Together, China and Russia now own 70% of the global titanium market.

Author Experience and Expertise

Peter Suciu is a Michigan-based writer. He has contributed to more than four dozen magazines, newspapers, and websites with over 3,200 published pieces over a twenty-year career in journalism. He regularly writes about military hardware, firearms history, cybersecurity, politics, and international affairs. Peter is also a Contributing Writer for Forbes and Clearance Jobs. You can follow him on Twitter: @PeterSuciu.